Views: 0 Author: Site Editor Publish Time: 2024-08-21 Origin: Site

Project Background

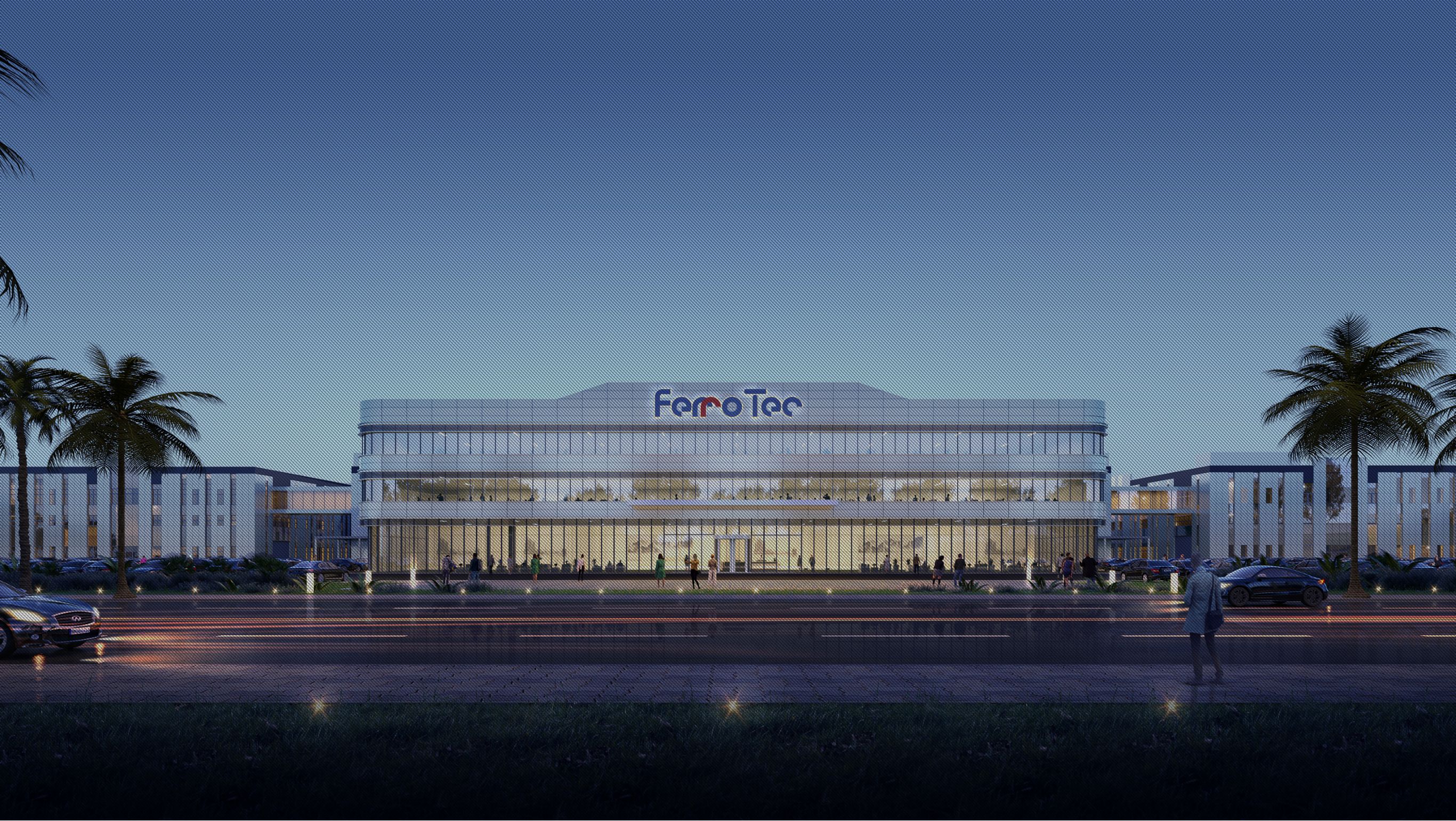

Ferrotec (Malaysia) Technology Development Co., Ltd. is a global leader in providing solutions for the semiconductor, electronics, and high-tech industries. As a company with extensive experience in semiconductor manufacturing, Ferrotec Malaysia faced the challenge of creating a lighting system that could meet the stringent requirements of its production environments. The goal was to improve the lighting quality in its factory and workshop areas, ensuring high production efficiency and maintaining the integrity of its precision manufacturing processes.

Challenges

In semiconductor manufacturing, lighting plays a crucial role in maintaining high production standards. Specific challenges included:

Lighting Stability and Uniformity: The production environment required stable and evenly distributed light to support precision operations.

Electromagnetic Interference: The lighting system had to avoid any electrical or electromagnetic interference that could disrupt the sensitive equipment and manufacturing processes.

Energy Efficiency and Low Maintenance: The lighting solution needed to be energy-efficient to reduce operational costs, while also being easy to maintain to minimize downtime.

Cleanroom Standards: Given the high standards for cleanliness in the manufacturing environment, the lighting system needed to be easy to clean and resistant to contamination.

Solution

To meet the needs of Ferrotec Malaysia, we provided a comprehensive, customized lighting solution designed to optimize the production environment in terms of lighting quality, energy efficiency, and operational effectiveness.

Precise Lighting Control

Our lighting system was designed with advanced control technologies to ensure uniform light distribution throughout the factory and workshop. This solution minimized shadows and light spots, providing consistent illumination for highly detailed and precision-dependent tasks, improving operational accuracy.

Electromagnetic Interference-Free Design

Understanding the critical need for electromagnetic stability in semiconductor manufacturing, our lighting products were engineered to be free from any electromagnetic radiation. This ensured that no interference occurred, preserving the integrity of sensitive production equipment and electronic instruments.

Energy-Efficient and Cost-Effective

The lighting system used the latest LED technology, which not only reduced energy consumption by over 50% compared to traditional lighting but also significantly lowered maintenance costs due to the long lifespan of the bulbs. This solution contributed to long-term operational cost savings.

Easy to Clean and Maintain

Our lighting systems are designed to meet the cleanliness requirements of high-tech manufacturing environments. They feature smooth surfaces and seamless construction to prevent dust accumulation, making it easier to maintain clean, contaminant-free environments. Additionally, the robust design ensures that the system operates reliably with minimal need for upkeep.

Customization and Rapid Response

We worked closely with Ferrotec Malaysia to provide a fully tailored solution that met the unique needs of their manufacturing environment. Our team provided quick, responsive support to address any technical challenges and ensure that the lighting system was seamlessly integrated into the production process.

Implementation Process

In the initial phase, we conducted on-site assessments and collaborated with Ferrotec Malaysia’s engineering team to analyze their specific needs. We then developed a detailed lighting plan, ensuring that the solution met the highest standards for both lighting performance and operational efficiency. During installation, we made fine adjustments to ensure the lighting quality and functionality met the client’s expectations.

Results and Benefits

By implementing our customized lighting solution, Ferrotec Malaysia significantly improved the lighting quality across their production facilities. The even distribution of light and stable illumination enhanced the precision of operations, reducing errors and increasing overall productivity. Additionally, the energy-efficient design resulted in reduced energy consumption, lowering long-term operational costs.

Client Feedback

"The lighting solution provided by your company not only improved the lighting quality in our production areas but also helped us achieve significant energy savings. After testing and implementation, we’ve seen improvements in production efficiency, and the system has been reliable and easy to maintain. We are very satisfied with this collaboration and look forward to working together in the future!" — Ferrotec (Malaysia) Technology Development Co., Ltd.

Conclusion

This project exemplifies how our lighting solutions can significantly enhance the operational efficiency and environmental quality in semiconductor manufacturing. Through tailored solutions and precise execution, we were able to meet the specific needs of Ferrotec Malaysia, helping them optimize their production process while reducing energy consumption and operational costs.